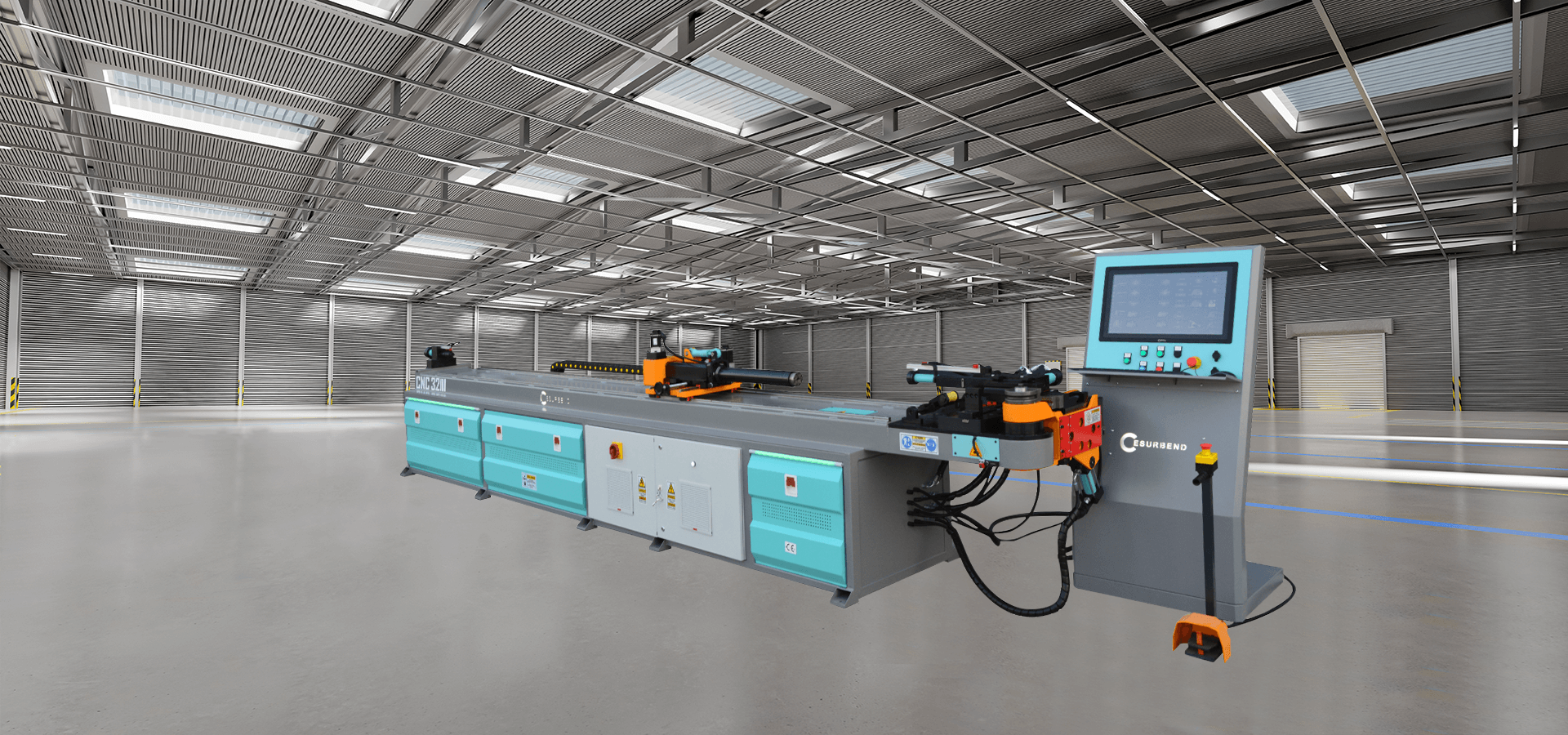

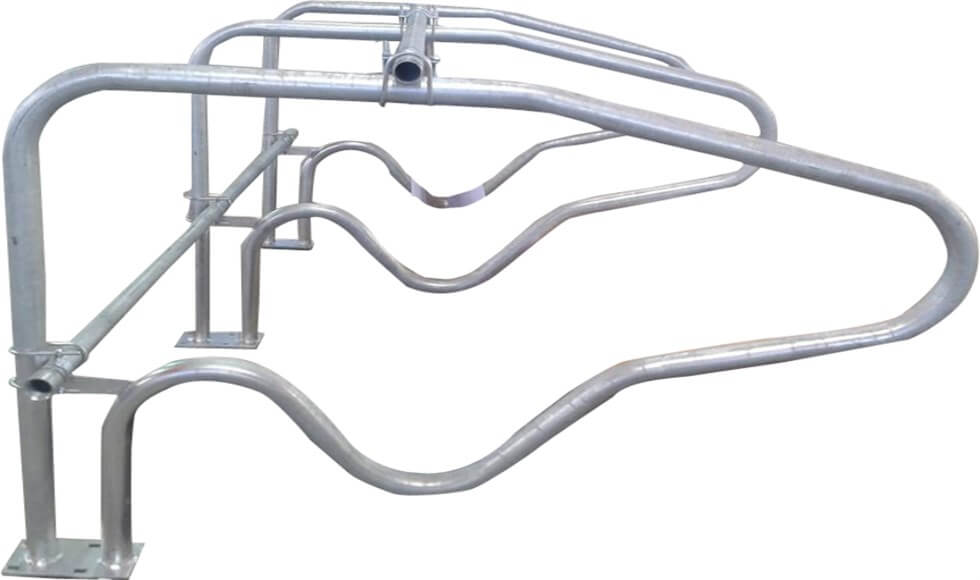

PBCNC-32 Pipe & Tube Bending Machine

Ask Us For More Information

Contact UsDownload Our Machine Brochure

Download- Product Features :

- • 21 ‘’ color touch PC (intel Core i5cpu Ram 8gb)• 2 Axis servo control (Y, B)• Bending axis controlled hydraulic (C)• 2 axial interpolation movement (Y, B)• Improved 3D Tubular Simulation• 3D Machine bending simulation (Colision)• Automatic pipe calculation• Motion PLC (Omron)• Safety OverEtherCat• Safety mat (750x1000mm)• 2D Drawing program (free)• All auxiliary movements are hydraulically operated(mandrel, clamp die, support, pusher, collet and shaft carrier)• Hydraulic oil cooling system (Electric)• Automatic lubrication system• Y Axis Linear Axis System• Security Switches• Pedal control• Manual and fully automatic operation feature• Working without mandrel and mandrel feature• Pulling feature while arming• Possibility to program in YBC mode and convert it to X, Y, Z, R format.• Line by line deletion feature in the program• Clicking feature in 3D pipe simulation (Y, B, C index viewing)• Converting X, Y, Z, R coordinates to Y, B, C, R format with a button• Conversion of a DXF format chicory to Y, B, C format with a button• Conversion of STEP format chicydosian to Y, B, C format with a button• Open and view file in STL format (compare with step file)• By defining the angle obtained after the first twisting of various materials to themachine, automatic calculation of the difference in the following bends and takingthe correct result in the bends• Cesurbend CNC software sends automatic reporting of all daily weekly monthly itemsto your e-mail addresses.• The feature of restarting from the place where the program is taken as a result of apower failure or an emergency stop and the ability to simulate it.• Showing work time• Possibility to receive remote assistance and updates• Compliance with standards

Technical Information

- Model

- PBCNC-32 Pipe & Tube Bending Machine

- Max. Pipe Diameter (mm)

- Q32

- Max. Wall Thickness (mm)

- 2

- Max. Bending Radius (mm)

- 225

- Max. Bending Angle (°)

- 190

- Bending Axis Movement

- 4 Kw Servo Motor (OMRON)

- Rotation Axis Movement

- 0.75 Kw Servo Motor (OMRON)

- Feeding Axis Movement

- 1 Kw Servo Motor (OMRON)

- Bending

- ± 0.1 mm

- Feeding

- ± 0.1 mm

- Rotation

- ± 0.1 mm

- Rotation speed

- 180º / sn.

- Feeding Speed (m/min)

- 1500 mm / sn.

- Bending Speed (r/min)

- 125º / sn.

- Max. Mandrel Pipe Receiving Length (mm)

- 4000

- Max. Boring length without mandrel

- Unlimited

- Min. Bending Radius (mm)

- 25

- Oil Tank Capacity (lt)

- 50

- Coolant capacity (lt/min)

- 50

- Max Hydraulic Pressure (bar)

- 140 kg / cm2

- Hydraulic Engine Power (kW)

- 1,5

- Machine Width (mm)

- 970

- Machine Length (mm)

- 5700

- Machine Height (mm)

- 1200

- Machine Weight (kg)

- 1200

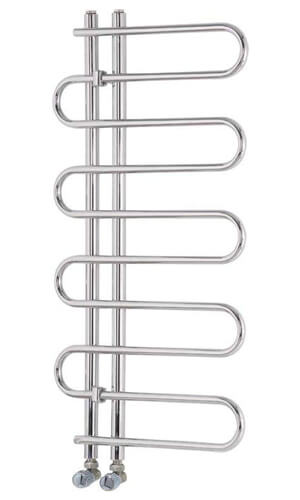

Usage Areas